Key Takeaways

- Findings from a University of Nevada, Reno, project indicate that higher education's need for 3D printing services could be both substantial and broad-based across disciplines.

- Users from across disciplinary and organizational boundaries quickly adopted a 3D printing service implemented in a UNR academic library, with the new printers operating at or near capacity throughout the service's first year.

- Anecdotal observation suggests that 3D printer access directly enables deeper engagement with and construction of knowledge.

Patrick "Tod" Colegrove is head of the DeLaMare Science and Engineering Library, University of Nevada, Reno.

The New Media Consortium (NMC) and the EDUCAUSE Learning Initiative (ELI) have repeatedly identified 3D printing as an important development in educational technology, most recently forecasting a mere two to three years before widespread adoption.1 What will that mean for higher education and society? How will such services impact practices of higher education and potentially learning itself? What can those tasked with provisioning such services expect and plan for?

In early 2012, the DeLaMare Science & Engineering Library at the University of Nevada, Reno (UNR), became one of the first academic libraries in the United States to provide 3D printing and scanning support as a library service explicitly available to all UNR students, faculty, and staff, as well as the public.2 Following a successful launch, the services were quickly adopted as a key component of the library's support of UNR's learning, teaching, and research missions.

3d Prints slideshow (1:00 minute)

Paradigm Shift

For more than a decade now, higher education has been undergoing a major paradigm shift, moving from teaching to learning as its primary focus.3 In response, academic libraries have been shifting from an emphasis on housing and archiving print resources to one of directly supporting knowledge production. When UNR's Chemistry Department faculty approached me as head of the DeLaMare Library in late 2011 with the suggestion that the library purchase a 3D printer as a shared technological resource for the university, the potential to catalyze learning and innovation across organizational and disciplinary lines seemed clear.4 The question was, If we build it, will they come?

After preliminary exploration, I raised the question with UNR Libraries' Emerging Technologies Team, a group of faculty and staff assembled from across the Division of IT & Libraries to vet such possibilities, and was quickly tasked with leading a small subset of the full team to explore the potential more deeply. What exactly is a 3D printer, and why should libraries care? Did a larger unmet need exist? Could the availability of such services foster learning and knowledge creation, and what would that look like? In the final weeks of the fall 2011 semester, the working group hosted a public event in the library's atrium to launch the discovery process, inviting students and faculty to join the discussion. Conversations started across library-supported departments and colleges extended to departmental labs and classrooms.

Doing Our Homework

The accepted wisdom behind the creation of a successful product or service is simple: find a need, and then fill it. The request that the library consider purchasing a 3D printer raised the possibility that the need for 3D printing services might extend beyond one department. If so, providing it as a library service might be a cost-efficient move that made sense for the university — and libraries have always provisioned community access to rare and sometimes expensive technology for the common good.5

Potential Benefits

The requesting chemistry faculty members believed that being able to "print" tangible 3D objects directly from digital computer models could transform their research and teaching. Similarly, the technology seemed to hold promise across disciplines for its ability to trigger further insights by

- enabling end users to go beyond data visualization on a computer display's 2D surface; and

- quickly producing a physical output that could be handled and examined in an active learning context.

Also, assuming the library could provide access to appropriate modeling software along with staff support, a 3D printer could enable and support rapid prototyping of experimental apparatuses and custom parts.

From the viewpoint of UNR's administrative and strategic alignment, provisioning a 3D printing service in the library could make sense as well: UNR Libraries' stated mission specifically mentions use of "cutting-edge technology" to further support "nurturing the production of new knowledge, embracing intellectual inquiry and innovation." The library occupies a unique position, able to leverage the depth of learning and opportunities for knowledge creation that access to such technology can provide. By its nature as a shared resource, the library potentially can serve as an active cross-disciplinary hub in which members of different communities of practice can serendipitously encounter and interact with one another. Rather than existing in isolated departmental technology pockets, shared library technology explicitly enables depth of learning and knowledge creation across disciplines. With appropriate encouragement and support, science, technology, engineering, and math projects can be augmented by insights from the Arts and Humanities, and vice-versa, in a self-reinforcing cycle in which "imagination begets fabrication, fabrication begets imagination."6

Early Analysis — and a Core Concern

Our initial explorations produced a preliminary possibility: Even as decades of ready access to computer workstations and productivity software — such as word processors and document printers — had gradually transformed how academic writing practice was learned and taught, 3D printer technology might similarly impact practice in higher education across the sciences, engineering, and the arts.

Just as a document printer lets users create a tangible product of their creative writing, enabling further refinement and collaborative input as it is physically marked up and shared with others, ready access to 3D printer technology could enable learners and researchers to quickly produce real-world versions of otherwise intangible digital objects. With the ability to transform digital models into physical objects that others could handle and examine in context — including being passed among collaborators and fit together with other real-world objects — the technology holds promise for triggering new insights and learning in a way otherwise impossible. From the realization of abstract mathematical surfaces, artwork, and mechanical prototypes to learning opportunities driven by reverse engineering or remixing of real-world objects, we found a broad-based eagerness to move forward across the disciplines we consulted.

However, our working group also had a core concern: was interest in 3D printing simply spurred by a popular trend and thus likely to fade quickly? Clearly, a thorough and cautious approach was called for.

A 3D Printer Technologies Primer

Our research revealed that, as a technology, 3D printing had existed for nearly 30 years. Although it had quietly transformed aspects of the manufacturing industry, the cost of entry for the equipment remained out of reach to the bulk of the education market. However, the 2004 expiration of a key 3D printing patent, followed by additional expirations in 2009 and 2010, resulted in a proliferation of hobbyist-class and open-source 3D printer designs. By early 2012, pricing for professional and commercial-grade options from well-established market leaders appeared to be coming within reach of the education market — even as numerous and rapidly proliferating entrants and options clouded what might otherwise have been clear and simple choices.

The working group quickly discovered that the deceptively simple phrase "3D printer" masked the reality of widely differing additive manufacturing7 technologies, each with distinct strengths, weaknesses, and applications. Differentiating among the underlying technologies helped us distill the seemingly broad range of choices within our library's budget to three off-patent technologies.

Over a period of several months, members worked to solicit input from potential service stakeholders and customers: students, faculty, and staff of the departments served. We found that, across disciplines, most individuals were already familiar with 3D printing as a concept and had been contemplating potential uses of the technology, though they were largely uninformed as to the variety of technological options and their associated strengths and weaknesses. As the working group members became more familiar with the underlying options, we became better able to bring value to the conversations on a particular technology's potential suitability for each contemplated use.

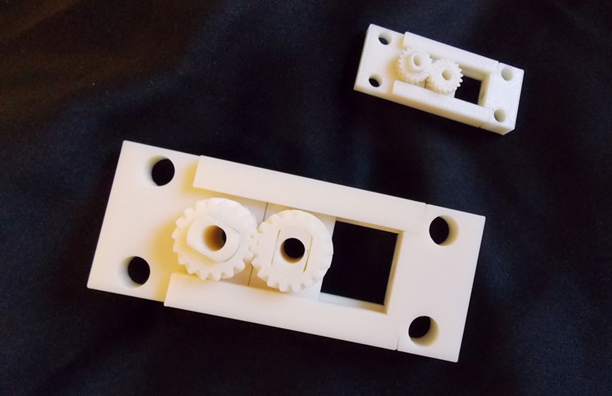

We also noticed a common need across disciplines: users wanted robust, "droppable" output that could be further machined if needed. Thus, the service would need to print 3D models of gears, robot parts, and models that could be handled with a minimum of breakage (see figure 1). As one faculty member put it: "Printing in color is nice, but we need a printer that can print in real plastic — something that can be sanded, drilled, machined, and dropped repeatedly without breaking." This would prove to be a key criterion, which helped us narrow the field of options. Printers that could print in impact- and heat-resistant thermoplastic materials — such as common Acrylonitrile butadiene styrene (ABS) plastic8 — were a viable choice. Printers that used binder jetting were attractive for their quick print speeds and ability to print in full color; however, the sandstone-textured output was fragile and couldn't be further machined without breaking. Of the printers we considered, those using light photopolymerization had the highest speeds and resolutions, but review and comparison of material characteristics of the "ABS-like" properties caused concern among the faculty consulted. Ultimately, only printers using thermoplastic extrusion remained in the final round of printers we considered for a pilot service implementation.

Figure 1. A working mechanical prototype with the requisite mechanical properties and multiple fully

articulated assembly pieces

Further investigations included lengthy telephone conversations with vendors, industry trade show attendance, and interaction with equipment under consideration. We supplemented these experiences with onsite visits and lengthy dialogue with a higher education venue that used a range of 3D printer technologies. We presented final recommendations to the UNR Libraries full Emerging Technologies Team; also, recognizing the potential value, we presented the proposal to the full faculty for final approval.

Knowledge Creation through Action

Rapid prototyping technology might not be appropriate in a traditional academic library. Nevertheless, throughout the discovery process — and fundamental to our proposal — we recognized that our potential support of such tools might well be a good fit for a knowledge center and campus hub of research and learning communities. Support of related technologies is not uncommon in the learning or research commons of the modern academic library; indeed, if "rapid prototyping represents the kernel activity of knowledge creation through action,"9 ready access to a 3D printing service is almost a natural next step. Although difficult to measure directly, a key indicator of success in both is the active construction and leveraging of new knowledge; it seemed likely that 3D printing services could enable — and even catalyze — the hoped-for outcomes in previously impossible ways.

Requirements and Concerns

We collected specific identified needs and details from potential stakeholders,10 including numerous potential opportunities to help students and faculty leverage the multidisciplinary skills and competencies required to innovate and compete in today's rapidly changing environment. Examples included

- designing and producing chemical models for both research and classroom learning;

- producing mechanical parts for various engineering coursework and prototyping needs;

- producing 3D topological or structural models across the geography, seismology, mining engineering, geology, mechanical, and structural engineering fields.

In addition to producing original artwork, various disciplines were interested in scanning and duplicating delicate source materials, enabling their use in the large classroom or teaching lab environment without risking damage or loss to the originals (see figure 2).

Figure 2. Partially painted 3D-printed duplicates with original source trilobite fossils (upper right)

Concerns about 3D printing included the potential requirement for adequate ventilation to safely operate. We closely examined the Materials Safety Data Sheets (MSDS) for printers' associated materials11 and consulted with our campus Environmental Health and Safety personnel about other potential safety concerns before making our final recommendations. We considered only printers requiring no special facilities — including ventilation above and beyond what might otherwise be readily available in the public library space.

Measuring Success

The working group presented its developed proposal to the entire faculty of UNR Libraries at an open meeting of the full Emerging Technologies Team, soliciting input and emphasizing that based on our research, rapid prototyping could well be an emerging multidisciplinary literacy — one whose support seemed poised to leverage learning and knowledge creation across the sciences, engineering, and the arts. When combined with more traditional technological offerings, a 3D printing service might be a significant step toward furthering the library's goal of providing an innovative environment designed to nurture creativity while stimulating and supporting innovation across the academic landscape.

Despite such lofty goals, success would be measured by a traditional cost-per-use metric. How many uses would it take to get the printer's cost per use down to that of a typical print book on a library shelf? Or, pushing harder, to get the cost to that of an electronic journal? Initial targets were set: after a hundred uses, comparable to a print book; a thousand uses, comparable to a typical electronic journal article used through the library.

Recommendations for the Pilot

We made three recommendations for the pilot implementation:

- Purchase two 3D printers: one higher-end printer capable of extended production use with a minimum of operator intervention, and a smaller/hobbyist-class machine portable enough to use at library outreach events. We chose the Stratasys uPrint SE Plus ($21,750) and the Bits From Bytes 3D Touch printer ($4,370), respectively; both can print simultaneously in a variety of ABS colors, with support material to ensure the ability to handle complex prints.

- Purchase the entry-level NextEngine 3D laser scanner system, complete with accessories and associated software. At a cost of approximately $7,150, the system would offer support for converting real-world objects into digital models suitable for rework by the service's end users.

- Implement the services on a strict materials cost-recovery basis to minimize the financial impact on end users and ensure maximal adoption without creating an additional ongoing financial burden to the library.

Following significant weeks-long discussions, a consensus was reached: UNR Libraries should go forward with the pilot implementation, funding the initial purchases of equipment and supplies internally with the stipulation that cost-recovery pricing would be developed and put in place to recover ongoing operational costs of the service. Precedent for cost-recovery pricing had already been established for similar library services such as large-format/poster printing and laminating: To establish a baseline for cost-recovery pricing, the 3D printing service would need to be offered at no cost until enough sample jobs had printed to enable us to identify, reliably predict, and recover the cost of consumables used by any given print. Once approved by the campus auditors, cost-recovery pricing could be established to avoid having UNR Libraries subsidize the service's ongoing use. From that point forward, customers presenting 3D print jobs would be quoted the final cost, with the print job released to the printer following payment.

Implementing the Service

Given approval by the UNR Libraries' faculty, we purchased the proposed equipment. News of the first printer's arrival near the end of April 2012 — scant weeks before the spring semester's end — spread quickly; within minutes a student posted the news to social media and teams of senior undergraduate students descended on the library service desk within an hour. While staff members unboxed the 3D Touch hobbyist-class machine, the students pressed library staff into attempting the service's first 3D print job: a pump impeller blade, part of one team's senior project to design a better pump.

Questioning revealed that, for two semesters, the students had been outsourcing the printing of their designed parts to a third-party print shop accessible via the Internet — despite costly overnight shipping and the fact that revisions could take weeks to arrive. The less-capable machine took nearly two days to complete the print, with multiple fits and starts; nevertheless, the students were thrilled to receive the print and immediately closeted themselves in one of the library's collaboration rooms in lively conversation while examining the object from all angles.

By all indications, the service was off to a successful start with its first 3D print job, facilitating deep engagement and active construction of new knowledge in ways not previously witnessed in the library; it was a pattern that would continue repeatedly as customers of the service began to experience a depth of learning and facility with the technology.

The second printer, the commercial-grade uPrint SE Plus, arrived and was installed nearly two months later. An unexpected requirement for installing the printer was the need for a dedicated 15 amp electrical circuit; the enclosed print chamber is maintained at a temperature of 175 degrees Fahrenheit, requiring significant operating energy input beyond that needed to melt and extrude the print materials. The printer also required proprietary software for processing 3D print stereolithograph (.stl) files. Unlike the hobbyist machine, which required manual transfer of print files to and from the printer by means of a USB flash drive, the commercial-grade machine received processed print files directly over a network connection directly to the printer.

We developed the service, including each printer's distinctly separate workflows and print queues, during the early summer months. All employees were strongly encouraged to familiarize themselves with the available resources and actively help develop each printer's associated workflows, including monitoring ongoing print jobs; catching and correcting malfunctions (such as print jams); and performing routine maintenance tasks. Such responsibilities were not that different from those associated with routine support of the library's text and other printer resources.

To encourage the in-depth engagement required for staff members to quickly acquire the facility needed to support the service, library staff members were tasked with locating and 3D printing an object in which they were interested. By introducing each person to the 3D model files on web-based resources such as Makerbot Thingiverse and Shapeways, the training shifted from a burdensome requirement into an adventure as each person identified, pursued, and ultimately realized layer by layer a uniquely personalized object.

From student worker to library director, each library employee was expected to have the operational facility to print that object successfully — without significant external assistance — prior to the start of the fall 2012 semester. We further set the expectation that, throughout the summer, the service would be treated as if already "live." 3D printing jobs would be accepted and processed on an ongoing basis to provide further learning opportunities and room for mistakes.

We developed a relatively simple spreadsheet to track the acceptance, progress, and contact information associated with each printing job handled by the service; a separate column of the workbook indicated which 3D printer was requested for each job. The regular and extended operator intervention required by the hobbyist-class machine — coupled with its natively coarser output and print speed (more than four times slower than the production-grade machine) — quickly relegated the hobbyist-class machine to use primarily for demonstration, outreach, and other liaison purposes. The 3D printing service quickly outstripped capacity: a print queue that typically extended days and even weeks quickly developed, requiring consistent handling and strict adherence to procedure. In practice, nearly a month passed before the evolving procedures and tracking had begun to acquire a semblance of routine.

A Pricing Model Emerges

We purchased the equipment in part using funds from student technology fees. As campus policy required that any charges associated with the technology's use could recover only operating costs, exclusive of power and depreciation, the library had to develop and vet a rational model for cost recovery that demonstrably did not make a profit before users of the service could be charged. During the initial semester, we offered 3D printing at no charge to customers to develop and demonstrate the model. Although we were initially concerned that end users might abuse the free service, a backlog quickly developed that seemed to discourage such abuse: When presented with the prospect of waiting several weeks before their job would print, only the most motivated users persevered.

Developing a rational costing model required a clear focus on the variables that could be known before a given model actually printed. The separate workflows associated with the UPrint SE Plus and the Bits From Bytes printers required processing the customer's .stl file to convert into printer-specific output; additional output from the software included separate estimates of the model's cubic inches and the support material to be consumed. These estimates were collected and logged in the tracking spreadsheet, along with an estimated print-completion time. The support material's volume varied as a function of model complexity; nevertheless, we opted for simplicity in the final model developed — the pricing would be based solely on the model's estimated print volume of material.

The dramatically different cost of print materials for the two printers, in conjunction with significantly differing print speeds and capability, argued strongly for developing separate cost models:

- For the uPrint SE Plus printer, a single spool of the proprietary ABS model material, containing 30 cubic inches, costs approximately $150, yielding a base cost per cubic inch of $5.

- The 3D Touch printer uses generically available 3mm model filament, which costs $70 for a two-pound roll containing 58 cubic inches, for a base cost of $1.34 per cubic inch.

Other costs include those associated with spools of polylactic acid (PLA) support material; replaceable parts associated with printer maintenance, such as replacement extruder heads and cleaning brushes for both printers; and, for the uPrint SE Plus printer, the sodium hydroxide (lye) used to clean printed models of support material. Figure 3 shows printing via extrusion of molten ABS material.

Photo courtesy of Nick Crowl

Figure 3. Multiple 3D objects being printed a layer at a time using extruded molten ABS material

3D printing a model on the uPrint in DeLaMare Library; note the active extrusion of yellow-colored ABS model material

For each printer, we divided the total actual costs of materials consumed over the initial semester by the summed total of cubic inches of the model material estimates to arrive at a base cost per cubic inch of model material. Although we successfully arrived at, vetted, and had approved cost-recovery pricing for the uPrint SE Plus printer, the lack of data associated with successful prints using the 3D Touch printer meant that we could not finalize pricing for the printer, which was subsequently taken out of service and transferred to the Art Department on campus.

Measured Use

We derived the following analyses from the information manually entered in the spreadsheet that tracked intake, progress, completion, and pickup of completed jobs for the first year of the service's operation (August 2012 through August 2013). To ensure data integrity, each entry was confirmed against a corresponding record in the printer's internal log file, including successful print completion, number of pieces, and cubic inches of the model and support material used.

Over the first year's operation, the 3D printers logged a total of 4,564.5 print-hours. Given the requirement of manual operator intervention to change out completed jobs and start the next job in the queue printing, the service was operating at or near capacity throughout the year with a limiting factor of operator availability off-hours.

Simply put, if the service had more capacity, more pieces would have been printed; many potential customers gave up because of excessively long wait times. Nevertheless, a total of 1,642 separate pieces were successfully printed, for an average of four to five pieces per day for each day of the year. The average piece consumed a total of 3.30 cubic inches of model and 0.78 cubic inches of support material to print. Midway through the year, enough data had been accumulated to transition the service to cost-recovery pricing; under that model, the average cost to the end user was $13.48 per printed piece.

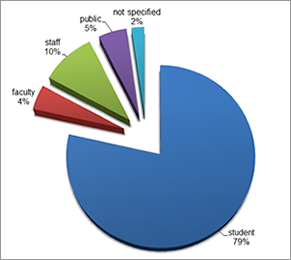

In an attempt to optimize the resource's availability for time-sensitive learning opportunities, we used the customer's stated purpose to quickly implement a priority-based system: jobs associated with student coursework received the highest priority and moved ahead of jobs supporting researchers, which were in turn prioritized over those for personal use or for the public. Figure 4 shows the distribution of service use by students, faculty, staff, and the public; we derived this information from customers' voluntary self-identification during the job intake process.

Figure 4. Distribution of 3D print jobs by self-

identified customer category

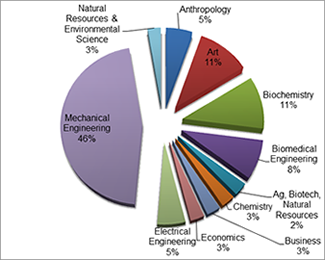

Figure 5. Distribution of 3D print jobs by self-

identified discipline of customers

Although not initially collected, the potentially more interesting findings derive from our subsequent collection of customers' self-identified discipline of study or practice. Figure 5 shows the distribution of use by discipline for the 109 print jobs nearest in time to the sample period — nearly 22 percent of the first year's total jobs — and provides a sense of the diversity of disciplinary use. Top service users were in mechanical engineering (46 percent), followed by art (11 percent), biochemistry (also 11 percent), biomedical engineering (8 percent), and electrical engineering and anthropology (both 5 percent). Although suggestive — and perhaps even surprising — such figures are qualitative rather than quantitative data, and the "undecided/not volunteered" category was omitted to enhance readability.

Discussion

Making 3D printing as a library service a reality in the library revealed a number of surprises — despite best efforts to research and develop the pilot in advance. Following are a number of practical insights gained from the first year of operation.

Service Costs and Support

Implemented in an academic science and engineering library, the 3D printing and scanning service appears to have met a cross-disciplinary need for a specific type of data visualization and rapid prototyping support, operating at or near capacity throughout its first year. Initial target goals for the cost-per-use metric were met and then exceeded: within the first year of operation, the resource's total cost per use had dropped substantially below that of a typical print book on the library shelf and even that of a typical electronic journal article used through a library subscription. Instituted on a cost-recovery basis, each subsequent use of the 3D printing service further lowers the resource's cost per use, further improving efficiency.

As implemented, the service was operated and maintained by the library's existing staff resources — that is, the same individuals who operate the library's service desks and check library materials in and out, while also serving as frontline customer support for the library's various IT resources. The 3D touch printer's overly complicated maintenance and repair demands quickly led to its being sidelined, while the relative simplicity of maintaining the commercial-grade printer facilitated its use.

Scalability

Despite the significant added demand of manually maintaining and tracking a lengthy print queue, the service even appeared scalable. With the single production printer operating at full capacity, the limiting factor is the speed with which the printer can complete each print. Although tempting to consider charting growth of the existing service, analysis would reveal little: it has been operating at capacity nearly since its introduction. The addition of one or more identical printers, however, could easily alleviate the limitations on the service without seriously increasing demands on staff.

File Errors

Also, despite the service's multiple potential failure points, the single biggest challenge proved to be inconsistencies and problems with the customers' .stl files. Many of the initial print failures were traced directly to errors in the presented file. Anecdotally, most files presented for printing contained such flaws. Relatively early on, staff members recognized and addressed the problem by modifying the intake workflow to incorporate the check and repair of print files using software such as the commercial netfabb and the open-source meshlab, occasionally in tandem. Given 3D printing software support's relative immaturity across platforms, inconsistencies appear to exist across implementations of the stereolithograph format. Those considering implementing a similar service might want to consider introducing the file screening and potential repair process prior to printing, if only to minimize the waste of time and material associated with print failures.

Usage and Discipline

Service use appears to be broad-based across disciplines and customer categories. The department that originally suggested that the library provide the service — chemistry — is far from the heaviest user; the need expressed was apparently only a small piece of a much larger (albeit unvoiced) need across disciplines. That most users appear to be associated with mechanical engineering and art is particularly interesting as both reportedly already had a 3D printing capacity — in mechanical engineering's case, for a number of years. On further investigation, we found that the resources of both departments share an aspect too common across higher education: the equipment had been purchased with one-time funding, but lacked the ongoing financial and human resources support required to provide and maintain the resource, so access to the equipment became limited. Preserved behind departmental walls for use by a few people, such resources have limited potential to catalyze innovation and leverage knowledge.

Despite predictable usage findings — that is, the majority of usage was from departments traditionally expected to use such a resource — other departments together used the resource nearly as much. We found a few surprises, as well, such as significant use by students and faculty from natural resources and environmental science, economics, and business. Still, it might be argued that precisely such involvement presents the most opportunity for innovation and knowledge creation.

Benefits

Although not measured separately, observation from within the library's active learning and research context seem to suggest that the service uniformly catalyzed engagement, depth of learning, and active construction of new knowledge that extended well beyond the library's walls. Consider the following three examples from the thousands of pieces printed since the service launched.

- Chemistry. Having done development work with a particular molecule for more than three years, a chemistry faculty member's progress had been blocked for months. In theory and according to all the visualizations he was running on a 2D computer screen, his model should have worked — but it didn't. After receiving the 3D printed model of the molecule and turning it over in his hands, within seconds a flash of insight: the approach he had been taking could never work. He simultaneously recognized a completely different approach that just might. By his own estimation, the insights gained from examining the print model shaved years off the time he would otherwise have spent working with the model on the two-dimensional screen of his computer workstation.

- Biotechnology. A graduate student spent months teaching himself the open-source and library-provided tools needed to crosswalk a specific protein structure's detailed structural data map, encoded in its protein database file, into a 3D-printable format. After a month of effort, the student had successfully 3D-printed a handheld model of the green fluorescent protein (GFP) that makes a jellyfish glow under fluorescent light (see figure 6). Passed with excitement from hand to hand throughout the student's biotechnology department, the model was quickly acquired by a high-ranking department faculty member for use as a teaching tool.

Figure 6. Model of the green fluorescent (jellyfish) protein

- IT Support. A particular mechanical plastic part in an aging laser printer model installed across campus developed a seemingly chronic failure mode. When an IT tech was called to repair one of these printers in the library, his frustration quickly gave way to inspiration: he recruited a couple of students and, on the spot, they jointly redesigned and 3D-printed a substantially improved part. Nearly a year and multiple campus installs later, the printers that received the improved part have yet to suffer a single failure. Also, the assisting students' demonstrated abilities earned them instant credibility — and even a degree of notoriety among their peers.

The successful provision and ongoing support of the 3D printing service seems to have broadcast a message across campus that the library is an effective partner when it comes to providing technological resources across disciplinary and organizational boundaries. This past year, faculty from across UNR's Colleges of Engineering, Sciences, and Arts joined forces with the Office of Research and Innovation to expand the fledgling services, putting significant financial resources behind the UNR Libraries' effort. A concerted and collaborative effort was mounted to identify and target resources that could be similarly shared more widely and efficiently. Subsequent funding directly from the Office of Research and Innovation targeted improvements that, among other things, include nearly tripling the existing capacity of 3D printing services while adding a high-end printer capable of 3D printing in full color.

With the relative explosion of commercial 3D printing services — from Shapeways to Amazon.com and even office supply stores such as Staples — the wisdom of outsourcing possible opportunities for learning and discovery off-campus comes into question. The recent availability of such services raises the possibility of further disintermediation, either by choice or as a default. Further, without a campus service to meet the needs of campus innovators, it is important to consider the potential for compromised intellectual property as faculty and students send materials associated with research and development to web-based third parties. Moreover, the falling costs for 3D printing equipment make provision of the services on campus increasingly attractive.

Conclusion

Despite initial misgivings, 3D printing as an academic library service was immediately adopted and incorporated into the library customers' learning and research lives. As an information resource, 3D printing seems a natural fit with other visualization resources in the library's learning commons and knowledge center. Augmented by the core value of offering equal access, the library's facilities are typically open and staffed hours longer than other campus offices, creating a benefit that those seeking to implement or more deeply support 3D printing capacity might consider.

The need for ready access to 3D printing services to support a university's learning and research missions has not only proven substantial but also broad-based. Despite heavy use and thus growing experience provisioning the service, at UNR Libraries we have only begun to explore the impact of 3D printing on the depth of learning, engagement, and innovation possible. Once familiar with the technological underpinnings of the currently available printer options, IT leaders and professionals across higher education will be able to successfully navigate the rapidly shifting landscape of 3D printer technology and support. In my experience, the potential benefits far exceed the investments.

Acknowledgments

This work could not have been accomplished without the direct support of the visionary faculty and staff across UNR Libraries and the former Division of IT and Libraries. Special thanks to Nick Crowl for his photography and graphical assistance.

- Larry Johnson, Samantha Adams Becker, Victoria Estrada, and Alex Freeman, NMC Horizon Report: 2014 Higher Education Edition, The New Media Consortium, 2014.

- Yvette M. Chin, "U. Nevada Library Offers 3D Printing Across the Board," Library Journal, August 7, 2012.

- David Arendale, "Leading the Paradigm Shift from Teaching to Learning," National Association for Developmental Education Newsletter, vol. 20, no. 3 (1997): 1; and the Boyer Commission on Educating Undergraduates in the Research University, Reinventing Undergraduate Education: A Blueprint for America's Research Universities, State University of New York, Stony Brook, 1998.

- Patrick Colegrove, "Rediscovering Relevance for the Science & Engineering Library," Brick and Click Libraries: An Academic Library Symposium Proceedings, Frank Baudino and Carolyn Johnson, eds., Missouri State University, 2012, 57–65; and Jason Hidalgo, "The Future of Higher Education: Reshaping Universities through 3D Printing," Engadget, October 19, 2012.

- Used in the root sense of the word; derived from the Greek roots techne (art, skill, technical know-how) and logia (dealing with word or speech), "technology" is fundamentally about the movement, transfer, and creation of knowledge by means of interaction and conversation. Library tools that have traditionally facilitated such transfer have evolved over many centuries from parchment scrolls and a proliferation of the print codex/book format post-Gutenberg to current electronic resources such as e-books, computer hardware and software, and a wide variety of supporting community-specific resources.

- Scott Doorley, Scott Witthoft, and David Kelley, Make Space: How to Set the Stage for Creative Collaboration, Wiley, 2011.

- A literal phrase; an additive manufacturing process creates output by adding material to an extended object. In contrast, subtractive manufacturing (also referred to as "machining") removes manufacturing material.

- The "common" Acrylonitrile butadiene styrene (ABS) plastic is not recommended for use in 3D printer systems because it requires special air handling due to the potential release of fumes during heating. Review of the Materials Safety Data Sheet (MSDS) associated with materials used can confirm the suitability of a particular printer material for use. For example, review of the data sheet for the "ABSplus" model material used by the uPrint Plus SE printer by the university's Environmental Health and Safety (EH&S) staff confirmed the manufacturer's claim that no special venting would be required to use the material in the library. Nevertheless, once the printer was installed and running, EH&S staff repeatedly sampled the air around the printer as an added cautionary measure.

- Martin Spraggon and Virginia Bodolica, "Knowledge Creation Processes in Small Innovative Hi-Tech Firms," Management Research News, vol. 31, no. 11 (2008): 879‒894.

- Copies of the internal proposal as approved and funded are available upon request; see also the section "How Is Rapid Prototyping a Match for Libraries?" in the blog by Lisa Kurt and Tod Colegrove, "3D Printers in the Library: Toward a Fablab in the Academic Library," ACRL TechConnect, July 17, 2012.

- As an example, consider the MSDS sheets associated with the FDM materials used in the Stratasys printer; the "Hazards identification" descriptions include null ratings for health, fire, and reactivity hazard. Once installed and operating, we took the additional step of having Environmental Health and Safety campus personnel sample the air near the operating printer on a regular basis to confirm the lack of particulate or other hazardous emissions.

© 2014 Patrick Tod Colegrove. The text of this EDUCAUSE Review online article is licensed under the Creative Commons Attribution-NonCommercial-ShareAlike 4.0 license.